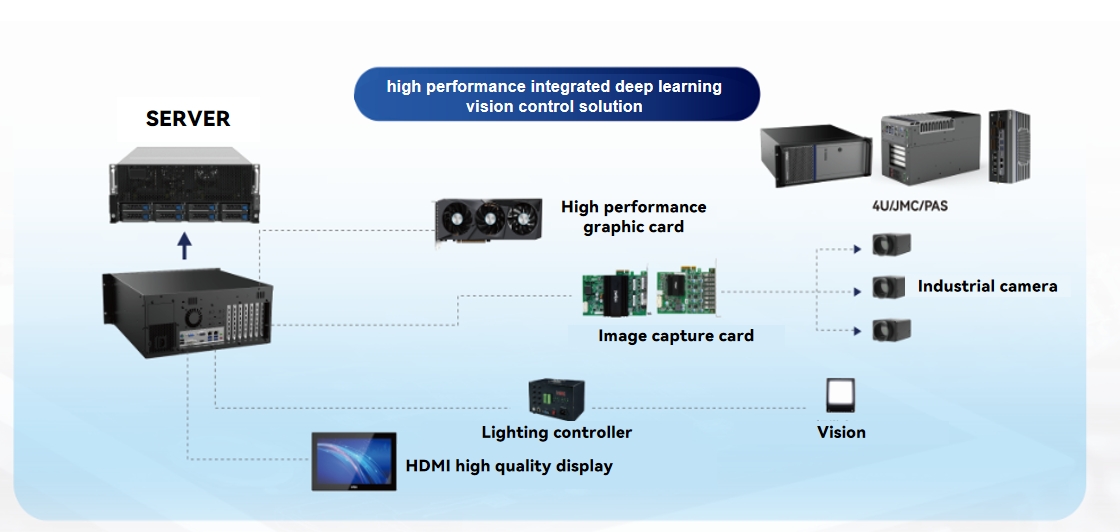

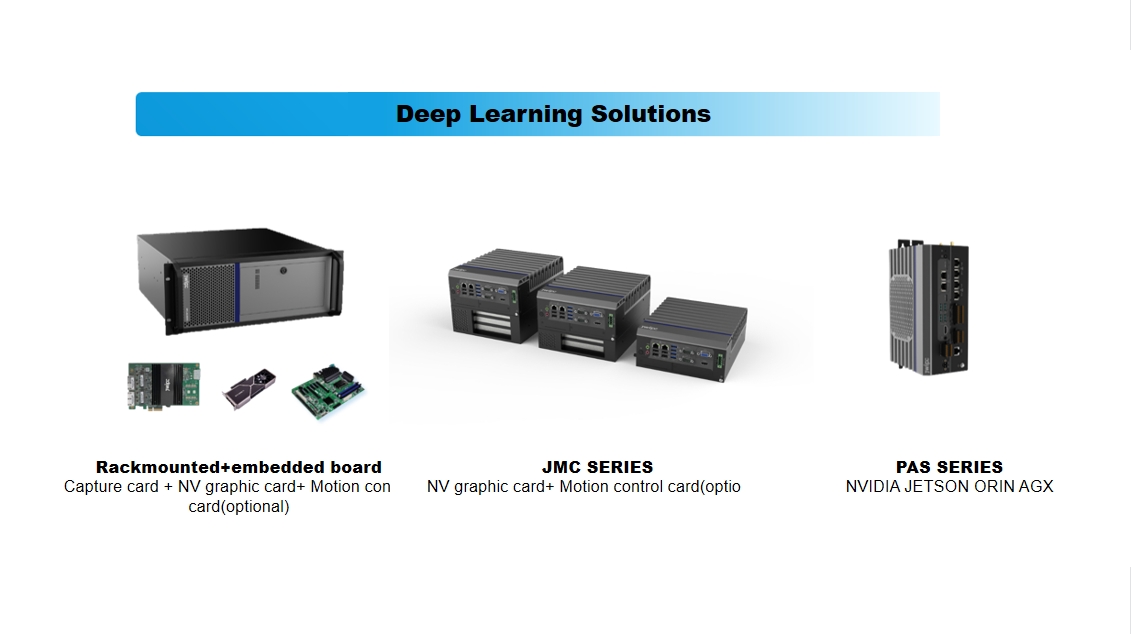

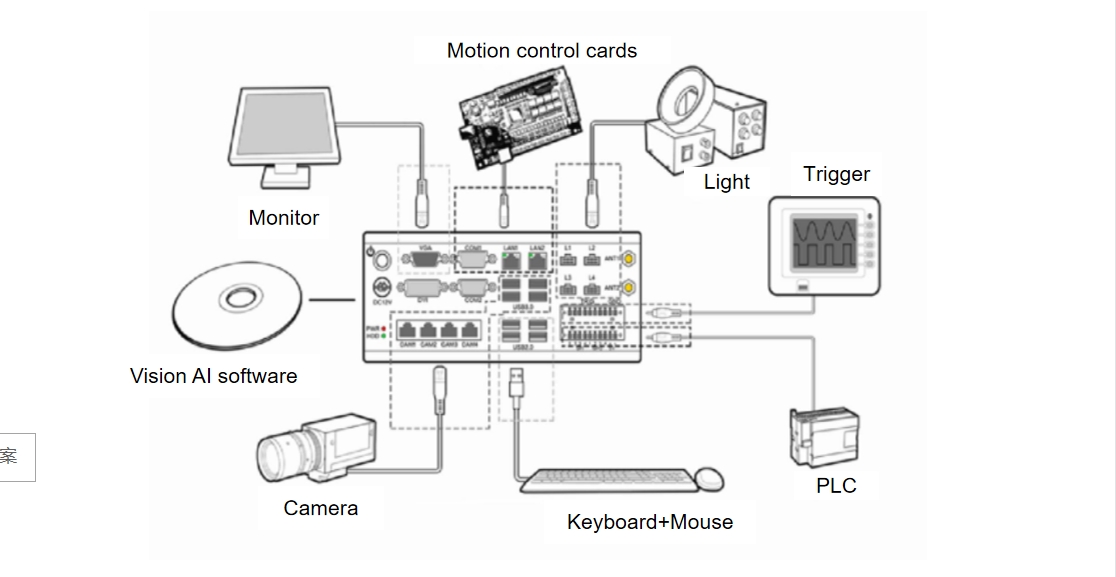

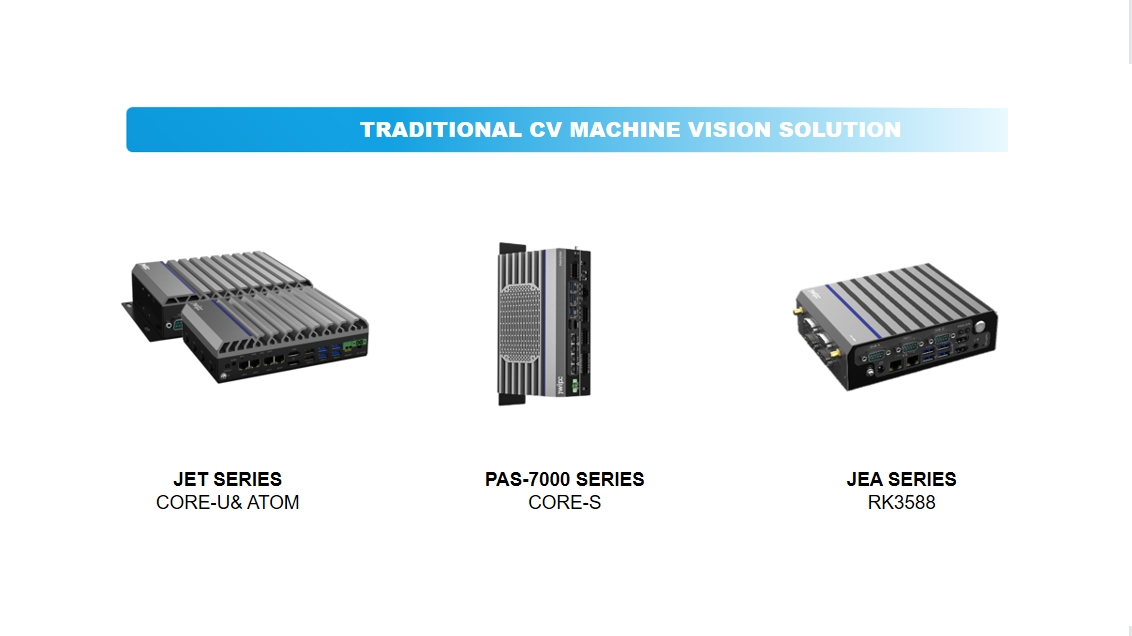

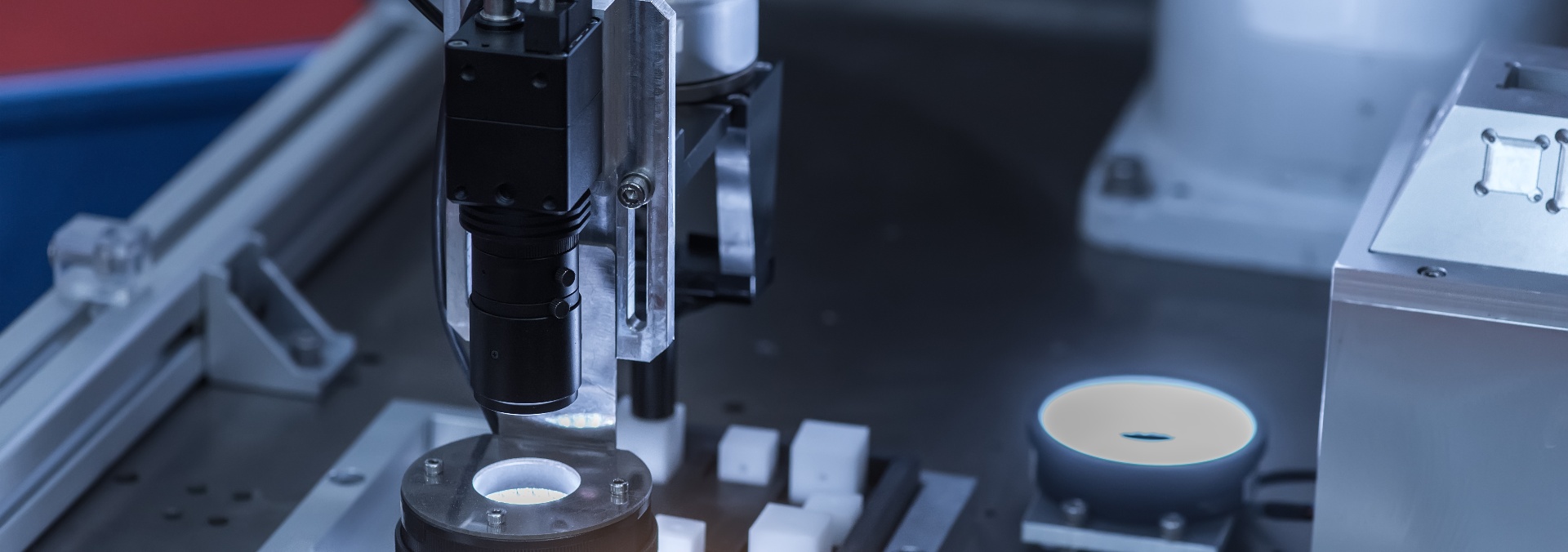

The global machine vision market is rapidly expanding. JWIPC's machine vision controllers provide professional and reliable solutions and hardware support for the machine vision industry, empowering companies to achieve intelligent manufacturing and sustainable development.