Education information plug in the wings of take-off to display, better embrace science and technology, change life

JWIPC offers tailored solutions covering everything from product definition to software and hardware development, supported by our experienced senior product engineers.

The professional consultant will call for feedback within 1 working day. Please be patient and wait

Education information plug in the wings of take-off to display, better embrace science and technology, change life

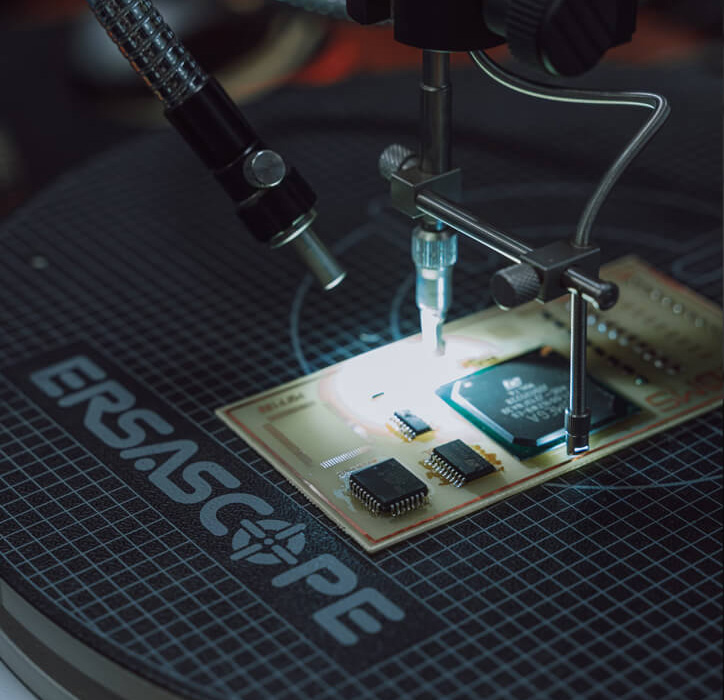

Our advanced facility enables rapid changeovers, faster deliveries, and flexible production. Specializing in R&D, manufacturing, and service for education/office, consumer electronics, network equipment, and cybersecurity sectors, we operate with fully independent R&D centers and wholly-owned production capabilities.

ISO9001, ISO14001, ISO45001, ISO27001, QC080000, IATF16949

Leverage core production data to deliver precise analytics, drive continuous improvement, and enable innovation. Our pure B/S architecture integrates cross-platform IoT and big data solutions to empower strategic decision-making

Scan the code to follow