With the rapid advancement of laser technology, modern laser processing equipment is marching toward larger-scale and higher-power applications. In these scenarios, the distance between control panels and processing areas continues to increase while electromagnetic interference (EMI) from high-power laser systems grows more intense. Traditional HDMI/DP display solutions, constrained by signal transmission limitations, struggle to deliver stable performance in long-distance, high-interference environments.

Addressing this industry challenge, JWIPC is introducing its innovative Laser Industry Solution, engineered to provide reliable support for laser processing operations.

JWIPC Laser industry solutions

Leveraging its extensive expertise in industrial computing, JWIPC has developed an integrated "Display + Vision + Control + Transmission" four in one solution. This comprehensive system supports laser processing, laser cutting, CNC machine tools, wafer laser applications, and photovoltaic cell/component laser equipment.

By incorporating high-precision vision algorithms, the solution enables ultra-accurate positioning, offers multiple online inspection capabilities ensuring superior product yield rates, and empowers intelligent equipment plus remote upgrade functionalities.

Display module

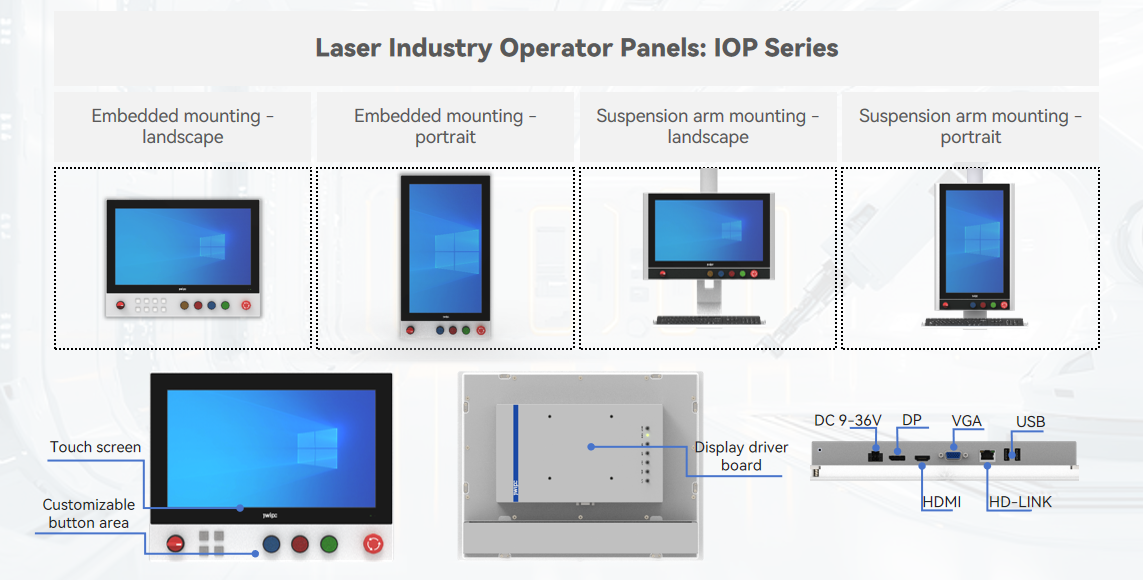

- The IOP Series Industrial Operator Panel features high integration and modular design as its core advantages.

Vision module

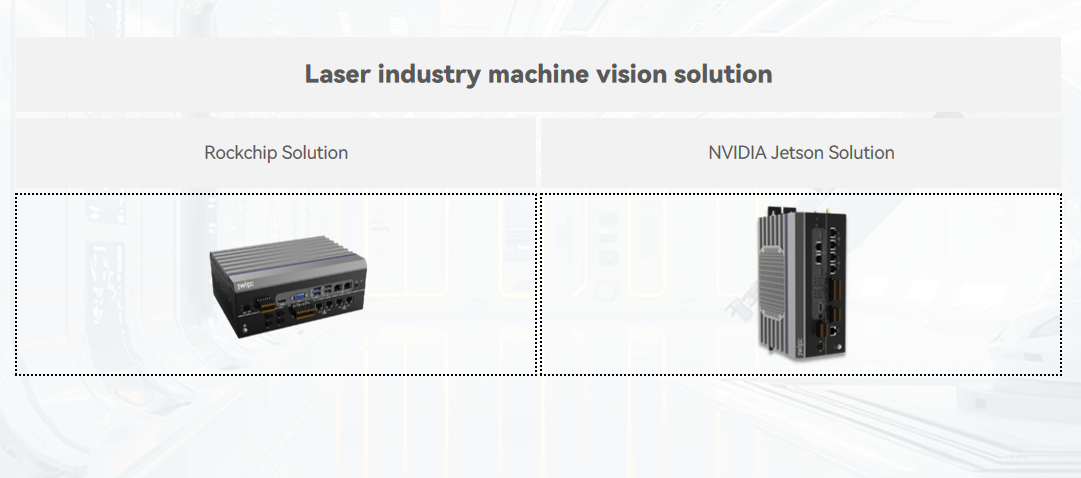

- RK3588 & NVIDIA Jetson PAS Series - Dedicated machine vision equipment enabling defect detection and path optimization.

Control module

- JEC-7120 controller delivers high-performance computing and data analysis capabilities.

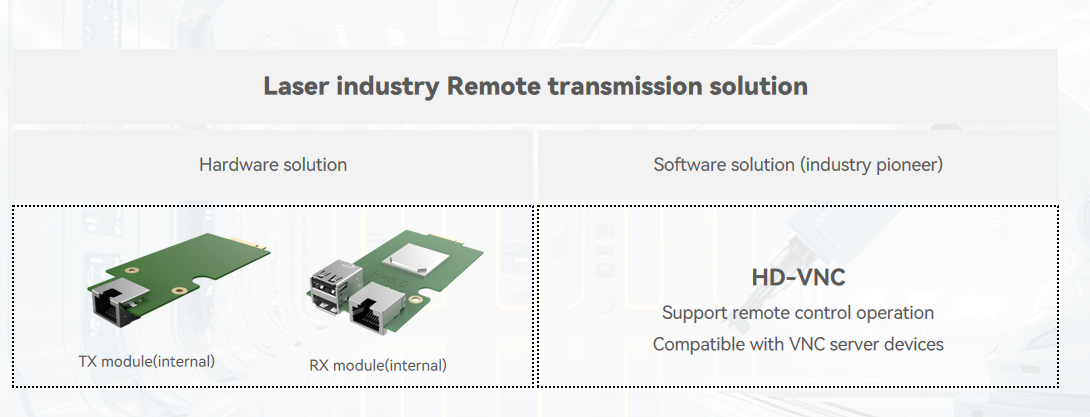

Remote transmission

- equipped with built-in HD-link hardware interface and HD-VNC software to meet diverse application requirements.

Laser Industry Solutions: Product Breakdown

Part 1:Display module

Flexible Installation Options

- Portrait or landscape screen orientation

- Multiple mounting methods: embedded or arm mounted

- Available in various sizes with expandable function keys

- Enhanced human-machine interface (HMI) experience

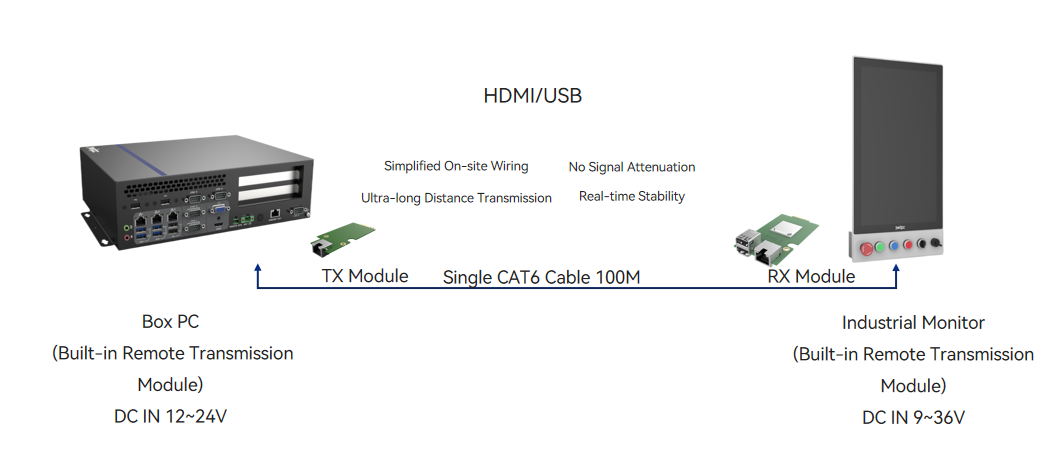

Long-Distance Transmission

- HD-Link remote transmission technology

- Simultaneous video + USB signal transmission via single CAT6 cable with a maximum transmission distance 100 meters

Industrial-Grade Protection

- IP65-rated enclosure (dustproof/waterproof/Shock-resistant)

Multi-OS Compatibility

- Supports Windows & Linux systems for diverse application requirements

Customizable Solutions

- Different panel dimensions selectable to match machine tool structures

Part 2: Vision Module – PAS-2000 & PAS-6000 Solution

Powered by Rockchip RK3588 & NVIDIA Jetson Orin, this solution integrates light source control and supports POE industrial cameras, delivering up to 275 TOPS computing power. It is widely used in intelligent applications such as path optimization, defect detection, and assisted positioning.

With quick migration and professional model conversion & precision optimization support, combined with the modular custom design of the PAS bus, it can reduce 40% of the development cycle, accelerating your solution deployment.

Part 3. Control Module – JEC-7120 Series Laser-Specific Controller

The JEC-7120 Series industrial computer is engineered for laser applications, featuring Intel Core-S processor and integrated remote transmission module, together with mainstream laser motion control cards and built-in light source control are ideal for laser cutting, welding, and other precision processes

Able to operate in different environments:

Cost-effective sheet metal version is equipped with vibration-resistant & anti-metal-dust design giving it high reliability and stability for harsh industrial environments

Fanless version is suitable for environments limited space

Compact version:

Compact form factor for space-constrained installations

Unified I/O panel layout:

All ports on one side for streamlined cable management

Expandable Functionality:

Supports PCIe/PCI expansion for control card and data collection card

Long-Distance Connectivity:

Able to be fitted with built-in remote transmission module, Support USB/HDMI signal transmission up to 100m

Part 4: Integrated Remote Transmission Solution – HD-Link & HD-VNC (Hardware + Software)

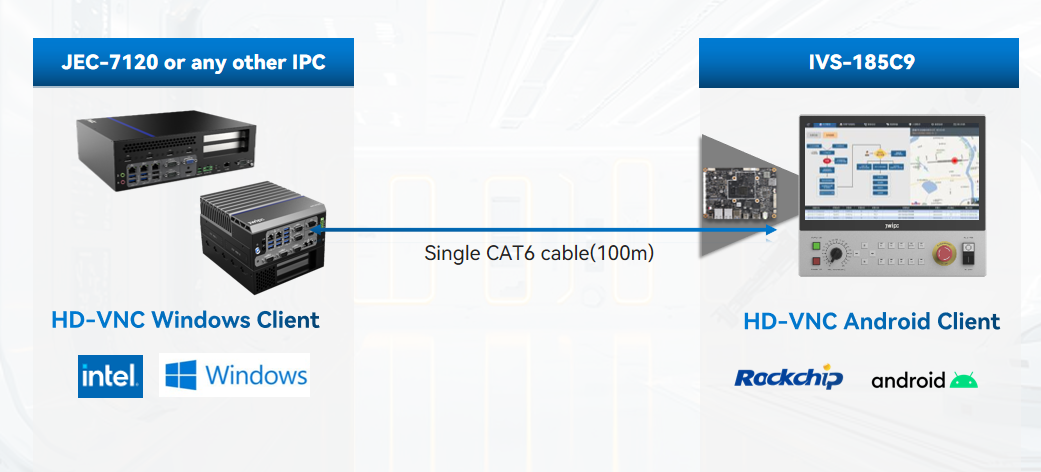

Builtin HD-Link hardware interface or optional HD-VNC software provide dual remote operation solutions, enabling 2K lossless long-distance display transmission.

HD-Link Hardware Solution

- TX module integrated into BOX PC and RX module built into industrial displays, eliminating the need for external transmitter chassis for enhanced stability

- Industrial-grade decoding chip ensures secure, stable operation

- Complies with HBaseT 2.0 standard (5Gbps bandwidth) zero latency, high-speed transmission

- Supports USB 2.0 devices (keyboards, mice, cameras, storage)

- 1080P/2.5K HDMI signals up to 100m

- No signal degradation or screen artifacts beyond 50m

HD-VNC Software Solution

- Industry Pioneering: Remotely control any VNC server device

- Default desktop program support, fast system startup

- support Tight encoding technology (≤80ms delay)

- support picture-in-picture mode and customizable gestures for multitasking

- TLS encryption for secure data transfer

Solution Advantages

1. "Display-Vision-Control-Transmission" Integrated Solution

Deep integration of four functional modules enables:

- 100m lossless transmission

- Real-time AI vision optimization

- Microsecond-level precision control

- Multi-protocol compatibility

- Breaks spatial constraints, reduces deployment costs.

- Delivers efficient, stable, and intelligent performance for industrial laser processing

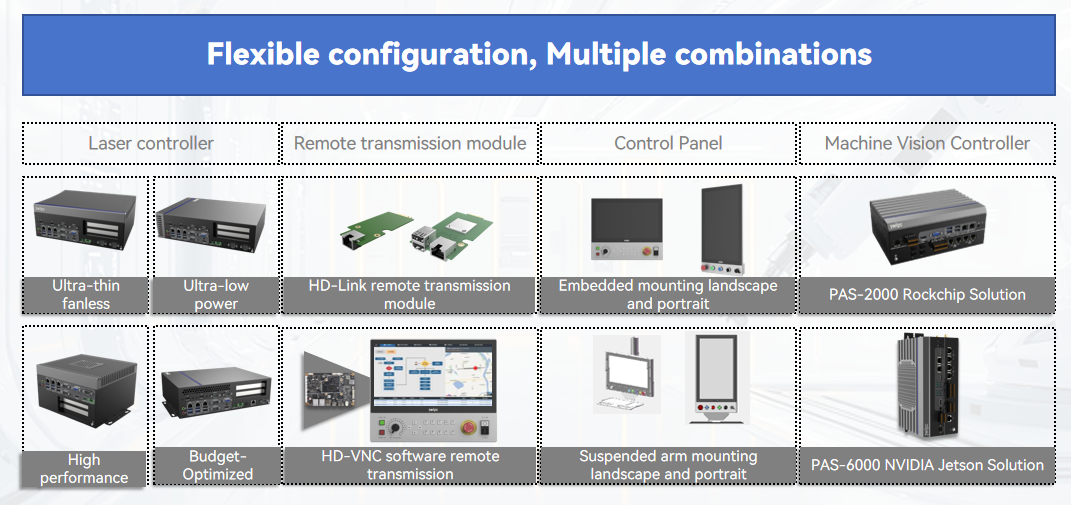

2. Flexible Configuration for Diverse Needs

- Selectable remote/non-remote modes

- Multiple combination options

- Supports various I/O interfaces + PCIe/PCI expansion

- Compatible with different laser equipment and control systems

3. Industrial-Grade Design Ensures Reliability

Full quality control process from IQC (Incoming Quality Control) to FQC (Final Quality Control)

Industrial grade protection:

- High-temperature resistance

- Dustproof & shockproof

- Suitable for harsh industrial environments

4. Customizable Control Panels

10-49 day delivery for tailored solutions including:

- Mechanical structure & dimensions

- Brand logo integration

- Touchscreen/button customization

5. AI Vision Enhances Production Precision

- Incorporates deep learning technology and combined with Machine vision capabilities.

- Support path optimization, defect detection, and assisted positioning.

- Improves laser processing accuracy and efficiency

Application Scenarios

Laser Cutting: Remote monitoring and cutting path optimization

CNC Machine Tools: High-precision machining for complex components

Wafer Processing: Precision control for semiconductor wafer dicing

PV Cell Manufacturing: High-accuracy laser-scribing improves yield

Laser Marking: Remote management with intelligent material recognition

JWIPC’s remote transmission solution combines PAS vision controllers, JEC-7120 laser controllers, and IOP operation panels to enable intelligent, end-to-end laser processing. Meeting industry demands for remote management, high-precision machining, and smart optimization, we continue to advance our solutions to progress the laser industry into the smart manufacturing era.